Coating process for zwitterionic polymer brush. Scheme 1 uses plasma-deposited 2-hydroxyethyl methacrylate (HEMA) to functionalize the surface with hydroxyl groups. The polymerization initiator, α-bromoisobutyryl bromide (BIBB), is immobilized to the hydroxyl groups. Scheme 2 uses plasma-deposited methyl 3-bromopropionate (M3BP) to functionalize the surface with the polymerization initiator. For both schemes, activators regenerated by electron transfer (ARGET) atom transfer radical polymerization (ATRP) is used to polymerize the zwitterionic material to the biomaterial. (Credit: Julia King, Prabhleen Kaur)

Zwitterionic Non-fouling Coatings

This work focuses on developing non-fouling and lubricious surface coatings for orthopedic implants and insulin-delivery catheters. Commercially available materials like plastics, metals, and ceramics possess the mechanical properties required for making medical implants but lack the desired biocompatibility. To enhance the biocompatibility and limit the extent of the foreign body response (FBR), zwitterionic polymer brush coatings are grafted to the surface of biomaterials to reduce protein adsorption–the triggering event of the FBR. Particular synthetic zwitterionic materials resemble the hydrophilic head group of a cell membrane’s lipid bilayer. These materials strongly attract water, thereby limiting protein adsorption and hence reducing the FBR. For our coatings, radio frequency plasma deposition of small molecules is utilized to functionalize the surface. Since the zwitterions are joined with a methacrylate, we utilize the popular atom transfer radical polymerization (ATRP) for surface grafting into a polymer brush.

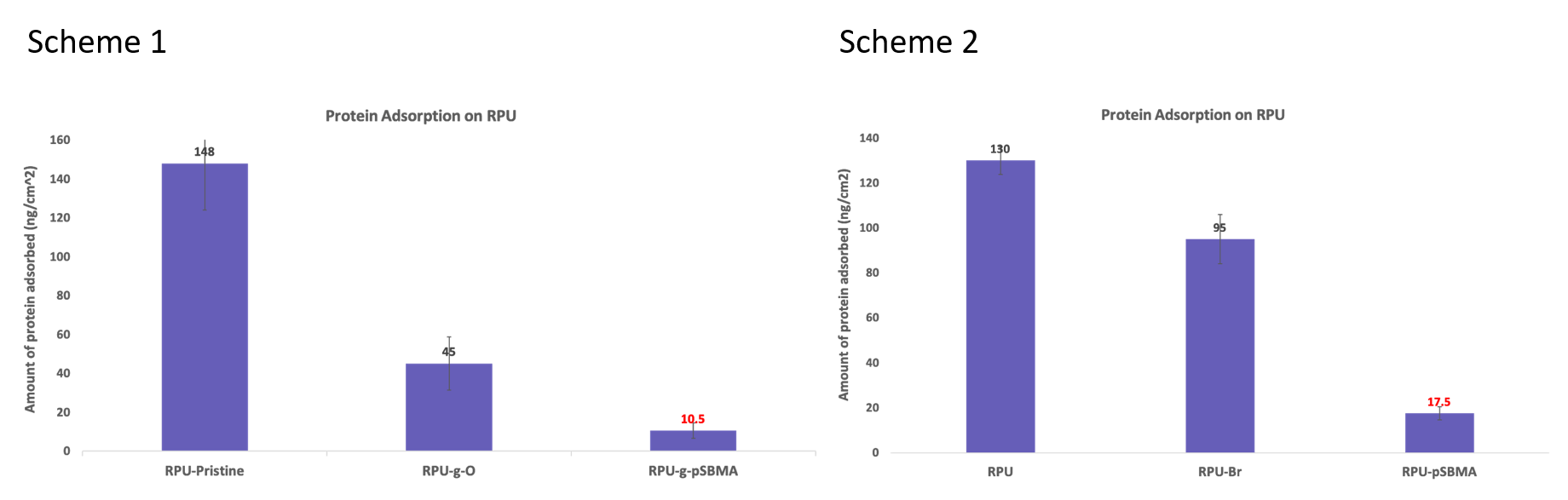

Our lab measures protein adsorption with an in vitro radiolabeled protein adsorption assay. We use albumin as the model protein and Iodine-125 as the radioactive agent for radiolabeling the proteins. Using a commercially available polyurethane based substrate (RPU-70), we were able to achieve a 93% reduction in protein adsorption using Scheme 1 and a 87% reduction using Scheme 2.

Another part of this research focuses on investigating the effect of molecular design of polymer brushes, especially grafting density and chain length, on their non-fouling and lubricating properties. The molecular design can be optimized to achieve reduced protein adsorption and surface friction, making the coated materials suitable for various orthopedic devices and other lubricious medical applications like syringes.

Protein adsorption results for grafted surfaces. Using Scheme 1, we achieved a 93% reduction in protein adsorption for surfaces grafted with pSBMA (RPU-g-pSBMA), in comparison to pristine RPU surfaces (RPU-pristine). RPU grafted with PHEMA (RPU-g-O), which was used as a control for low fouling surfaces, also showed reduced protein adsorption. Using Scheme 2, we achieved a 87% reduction in protein adsorption for surfaces grafted with pSBMA (RPU-pSBMA), in comparison to pristine RPU surfaces (RPU). (Credit: Julia King, Prabhleen Kaur)

Keywords: zwitterionic, biocompatibility, ARGET-ATRP, M3BP, polymer brush, graft

Active Researchers: Prabhleen Kaur, Julia King