Logger sitting on a heavy rigging block, Clemons Logging Company, ca. 1930

(University of Washington Clark Kinsey Photographs Digital Collection)

A Curriculum Project for Washington Schools

Developed by Tim Wright

Olympic Peninsula Community Museum

in partnership with the University Libraries,

Center for the Study of the Pacific Northwest,

and the Department of History at the University of Washington

Curriculum packet PDF

I. High-Lead Logging

Introduction

Italicized words are explained in the Glossary of Logging Terms.

The tip of the Olympic Peninsula offers a case study on the intersection between technology, market demands, and resource exploitation. Although early European and American visitors had noted its dense forests, filled with trees of enormous girth and height, the region’s lack of suitable harbors—ports located within a mile of the most marketable timber—limited the timber that could be profitably harvested and moved to market—especially when more accessible timberlands were available throughout the region.

It was not until a railroad line from the mills at Port Angeles began to snake toward the small town of Forks in the first decades of the twentieth century that lumber became a significant economic activity on the western edge of the Olympic Peninsula. There the industry experienced a series of booms beginning with the First World War—when the area was logged for the spruce used in aircraft construction; in the 1920s as the demand for pulp-woods rose; and, then, sustained growth from the Second World War peaking in the 1970s when a convergence of market demand and liberal federal policies opened large tracts of public lands on the peninsula to logging. Also, advances in technology, particularly high-lead yarding, the chainsaw, and the growing use of trucks made it possible to profitably log areas that in earlier years would have been bypassed.

High-lead yarding was, perhaps, one of the biggest advancements in logging in the early part of the century. Prior to its introduction around 1910, the timber industry used groundlead yarding. That required dragging bucked logs—trees cut into manageable lengths (Figure 1)—through the forests to landings where the logs were stored until they could be transported to the mills (Figure 2). In the early years of logging on the coast of Washington, draft animals provided the muscles to move the logs to the landings. Teams of horses or, more often, oxen hauled the logs over skidroads to the landing (Figures 3 and 4). These landings were typically on a body of water where the logs could be floated and then towed to the mills in rafts. The constraints of this process typically limited logging to within about a mile of a usable waterway.

Background

Groundlead yarding took a giant leap forward in the 1880s when steam-driven donkeys replaced horse- and oxen-power. Now logs were dragged along the skidroads using a system of cables and blocks driven by steam donkeys. The mainline was attached to single logs or turns of them and then wound up on a large spool powered by the donkey, pulling the timber along skidroads that were up to a mile long. The first donkeys had only a single spool and the mainline cable and butt rigging had to be dragged back to the cut timber by a draft animal (Figure 5). Very quickly, however, a second spool was added for the haulback, a cable that pulled the mainline and rigging back to the worksite so it could be attached to another turn. While the mechanical power sped up the process and made it more dangerous for loggers and the rigging crew, the basic principles of skidding the timber from the worksite to the landing remained the same.

The introduction and extension of logging railroads, arriving on the Western Olympic Peninsula around 1900, removed the need to cut timber near large waterways (Figures 6 and 7). Narrow-gauge railroad spurs could now be run to areas remote from rivers, lakes, or the coast, opening them up to logging. Initially many of these railways terminated at a log dump along the coast where the timber could be sorted, formed into rafts, and then towed to mills (Figures 8-10). Coastal communities like Port Crescent, Gettysburg, Twin, and Pysht blossomed quickly but also, just as quickly, wilted as the newly accessible timberlands were cut down or the extension of the railroad made it possible—and affordable—to transport the logs to the mills by rail.

New Technologies

During World War I the demand for spruce—used in aircraft frames—and the intervention of U.S. soldiers to quell labor unrest and accelerate spruce production led to the development of extensive, government-financed infrastructure improvements, including a 36-mile extension of the railroad line from Disque Junction, nineteen miles west of Port Angeles, to Lake Crescent and then to Lake Pleasant, eventually terminating at Tyee, about eight miles from Forks.The last spike on the track was driven home on November 30, 1918, nineteen days after the war ended.

The railroad was sold to private investors in 1922 and, in 1925, incorporated within the Port Angeles and Western Railroad. Within a few years, the line was extended to Forks, serving the logging community until the railroad company abandoned it in 1954 due to lack of revenue and lawsuits stemming from the Great Forks Fire of 1951. By then trucks were carrying most of the logs to mills (Figures 11 and 12).

At roughly the same time railroads were starting to make their mark on the Olympic Peninsula, the timber industry was undergoing a revolution in logging methods, shifting to high-lead, or “flying,” yarding. Combining the mechanical power generated by donkey engines—mostly run on steam— with a system of cables and blocks rigged overhead among the trees in a tract of timber, high-lead yarding transformed logging on the peninsula. It both sped up the pace with which an area could be logged, but also made it possible to harvest trees in areas—such as ravines—that had been inaccessible to more traditional, groundlead logging. From the First World War well into the post-World War II years, high-lead logging remained a dominant pattern of timber harvesting on the Olympic Peninsula.

How it Works

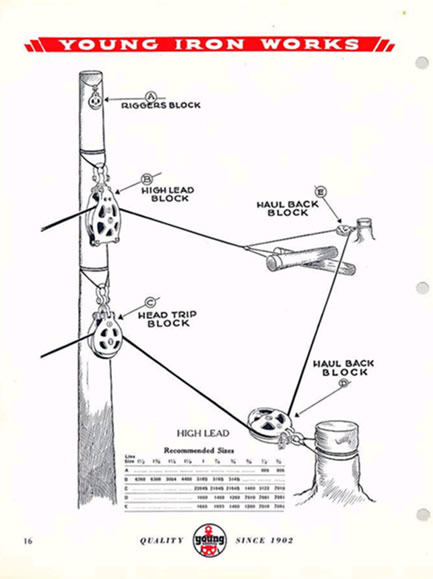

By the 1920s the basic technology of high-lead yarding had been worked out and refined. The operation centered on the use of one or more donkey engines running a series of cables, called “lines” or “wires” by the loggers who worked with them, rigged through blocks attached to a spar-tree. The basic set-up, as illustrated in the Young Iron Works catalog, is shown in Figure 13, above (Note that the scale in this image is distorted. At the logging site the lines and blocks could extend up to a mile or more from the spar-tree.)

One of the first tasks was to locate a suitable spar-tree. This tree was meant to act as the centerpost for the network of lines that would reach out into the brush to grab the logs and pull them in to be stacked, rather like straws, in a loose pile called the cold-deck. The spar tree had to be trimmed of its branches, “topped” (the top portion of the tree, beyond the highest portion of the rigging, was cut off), and then rigged with a series of supporting guy wires, an assortment of blocks, and working lines. The guy wires kept the spar-tree upright under heavy loads while the blocks carried the lines that would drag and lift the logs as well as haul the lines back to the worksite.

Although in the early years of high-lead yarding spar-trees were of modest heights—the highest might be seventy-feet tall, about the same height as a six or seven story building or, perhaps, between two and three times taller than a telephone pole—by the 1920s it was commonplace to see logging operations using spar trees that were 150 feet tall. In several places, spar-trees were even topped at over 200 feet. What allowed the use of such mammoth trees was the development of the high-rigger. This was a logger who used climbing spikes attached to his boots and a wire-cored rope looped around the tree to climb the tree. Prior to that, loggers had built ladders or used springboards to scale the tree. Now head-riggers could walk up the side of the tree, using a short-handled axe to trim branches they went (Figure 14). When they reached a point at which the diameter of the tree narrowed to between about three or four feet, they would use the axe to top the tree. As the topped section fell away, the head rigger would hold on tightly as the tree top, released of its load, swung in arcs (Figures 15 and 16). Some head-riggers used explosives, blowing the top of a tree off with dynamite detonated with a slow fuse that was intended to give the rigger time to get to the ground and get clear.

Variations

Once the tree was topped it was time to rig the trees: placing the guy wires—there were typically two sets: one attached to the top of the tree, the second about halfway up (Figure 17); “hanging” the blocks; and running the working lines through the blocks (Figure 18). It was heavy work: the mainline block on a spar-tree usually weighed hundreds of pounds. (Figure 19). It was hoisted up using a small block lashed to the almost the highest point of the tree. Once rigged, the spar-tree was ready to start moving logs (Figure 20).

The configurations of high-lead rigging were many and depended on the purpose of the system. One system might yard the logs from the worksite to the cold deck while another was set up to take the logs from the cold deck and load them on to train cars or trucks. Loggers working in extremely steep terrain might even rig a system that worked like an aerial tramway, swinging cut logs from one ridge to another. Several of these systems are illustrated in Young’s catalog, pages 18-28 and 32-35 and in Figures 21-25.

As the rigging crew often worked out of sight of the donkey punchers who controlled the motion and speed of the mainline, orders where communicated via a series of whistle blasts controlled by a whistlepunk who pulled a thin cable connected to the whistle on the donkey engine. The whistlepunk would indicate whether the chokers had been attached to the logs and if it was safe to pull the log to the cold-deck. It sometimes wasn’t and the risk of injury or death in the forest was high.

Despite the use of high-lead yarding, groundlead yarding still had a place. As the technology advanced, however, undlead yarding became the province of gasoline or diesel-powered tracked tractors that would drag the cut timbers to the landing using a variety of techniques. Three of these are illustrated in the Young Ironworks catalog (Figure 13).

Conclusion

On the Olympic Peninsula, as elsewhere, logging technology was never static. The timber industry always sought to develop new ways to harvest timber and move the logs to market. High-lead logging is a good example of this trend. It both sped up how quickly trees could be yarded as well as made it technologically possible to log areas—such as steep hillsides and ravines—that were inaccessible to more conventional groundlead yarding. Combined with the extension of railways it now became possible to harvest timber from large areas of the Olympic Peninsula and fuel the economic growth of the region for more than fifty years.

II. Instructions on Becoming a Logger

D. D. Strite, How to Become a Logger: A Complete Treatise in Six Lessons. Portland, Oregon: The Timberman, 1924. pp. 2, 8-13

Introduction

Written in a spirit of fun under a bunkhouse lamp, this little book by a logger gives an accurate account of the daily life of the men who get out the big logs in the Douglas fir region of Oregon and Washington. It is, we suspect, a few chapters from his own experience in breaking into the game. The author is D. D. Strite, Jr., of Idaville, Ore., the headquarters camp of the Whitney Company, Limited. The cartoon illustrations are by the author.

….

Lesson II: Acquiring a Vocabulary

In this lesson we intend to instruct you sufficiently in the language of the woods to enable you to carry on an intelligent conversation with the bull cook or other high company officials.

Now bear in mind that the Big Three of logging are donkeys, lines and blocks. When you are able to ‘punch’ a donkey, ‘buck’ 2000 feet of straw-line and ‘hang’ a block you’ll be a man, my son, for a’ of that. To the untutored brain, punching a donkey might seem like a ticklish occupation. However, once that you have discovered that the donkey is not one of the long-eared variety the situation becomes less involved. The much-cussed and discussed species of steam engine known to the profession as a ‘donkey’ is to the logging game as the mainspring is to your dollar watch. It’s the source of power that makes the wheels of industry go ’round and ’round. The important function of the steel cables, called ‘lines’ for short, is the same fishing or logging. The drums on the donkey spool the line like the reel on your fishing pole; the butt rigging represents the spinner with the choker as the hook; and the log, of course, takes the place of the fish. … To ‘buck’ means to pull, and by the time you’ve bucked a thousand feet of line and given up any hope of there ever being an end to it someone ’way off will yell ‘Line!’ and they’ll stop ‘taking it away.’ Then you’ll try to straighten your back and find that that portion of your anatomy has become petrified. While you are trying to recall the permanent disability clause in your insurance policy, the head rigger will hook on to the haulback and yell, ‘Ahead on the guinea!’ The steel line that has been lying so harmlessly at your feet will become a living thing! It zips past your ear and knocks off your hat! Undoubtedly your recent petrification will be forgotten in the rush to get ‘in the clear.’ A block in civil life is spoken of as a pulley. In the woods it is very often referred to as a ______ ________ __________ ________. The lines from the donkey pass through various kinds of blocks. To ‘hang’ a block doesn’t necessarily incur the liabilities brought about by the ordinary type of lynching. Your boss will point to an object on the side of some distant peak and say, ‘See that hemlock this side of that rain cloud?” You nod and take another pinch of ‘snoose.’ ‘Hang a trip block up there,’ he murmurs gently. The idea is to take your bearings and boost the block up on your back …. If the hill isn’t too steep you should arrive at the designated hemlock by the afternoon of the second day.

“The Golden Rule of the woods is to keep out of ‘the bight of the line.’ The bight of the line is the place you will always find yourself when ‘the rigger gives the punk the highball’ (or, in other words, when the man in direct charge of the crew in the brush signifies to the young man manipulating the whistle wire that he, the rigger, is now prepared to have the donkey haul in the log, untechnically speaking). When the main line tightens up it may sing harmlessly over your head, or again it may sign a different tune about five feet above the soles of your shoes. In the latter case, unless you stand four feet ten and three-quarter inches in your boots, the rigging crew will put in the rest of the afternoon gathering up the pieces. Next day the papers will very simply announce in the death column that ‘Yesterday’s fatalities included one woman, two men and a logger.

“You will find that actual logging operations are carried on by whistle signals relayed over the wire from the ‘whistle punk’ in the brush to the donkey engineer on the landing. The whistle punk is usually about 16 to 18 years old and the hardest boiled egg in the outfit. He is usually deaf, dumb and blind, according to a report in ‘The Hooktenders’ Gazette.’ An important part of your education is to learn the whistle signs. For the present, however, it will suffice to know that a long and a short whistle means quitting time. This is the most important signal.”

….

“If the ‘push’ (i.e. the camp foreman) should tell you some nice wet morning to ‘chase the swing,’ don’t laugh. He doesn’t intend you to go hunt up a board and some hemp rope to rig up a swing for his little boy to play on. All you have to do is to go down to the landing and unhook the logs when they’re hauled in from the brush. You are then a ‘chaser’ and ‘the swing’ is the name given to the donkey which is used to relay the logs from the yarding donkey over across the river to the landing where they’re loaded on cars.

“It would require a good-sized dictionary to explain all the strange words you will hear in the brush. In time you will acquire the lingo and talk as fluently of these mysterious things as does the young whistle punk in town on Saturday night….”

III. Loggers’ Whistle Signal Codes

The Timberman, February 1930

Pacific Logging Congress

High Lead Signals

- / one short / Stop

- – / two short / Come back on haulback

- – – / three short / Come ahead easy on main line

- – – – / two short and two short / Come back easy on haulback

- – – – / four short /Slack the main line

- – – – – – – / two short and five short / Slack the haulback

- – – – – / three short and two short / Tight line

– – – / three medium / Hooktender. Followed by three short, call in crew

— — – – – / two long and three short / Donkey doctor

— — — – – / three long and two short / Climber

— — — / three long / Locomotive for switching

— — — — / four long / Foreman

— — – / two long and one short / Oil

— / one long / Stop oil

— — / two long / Water

— one long / Stop water

— — — — — — / six long / Man hurt, locomotive and stretcher

— — — — – – – – – – / four long and six short—repeat / Fire

- – – – – – – – – – / succession of shorts / Danger, blasting at landing

— – / one long and one short / Starting and quitting

Locomotive Signals

— — — — / four long / Foreman

— — — — — / five long / Section crew

— — — — — — / six long—repeat / Man hurt, stretcher

— — — — – – – – / four long and four short—repeat / Fire

Butt Rigging Signals at Tree

- – / two short / No choker

- – – / three short / Strawline

- – – / two short and one short / One choker

- – – – / two short and two short / Two choker

- – – / one short and two short / Bull choker

The above Logging Whistle Signal Code has been adopted by the Whistle Committee of

the Pacific Logging Congress as standard for Pacific Coast Logging Operations.

IV. Glossary of Logging Terms

The timber industry, like many professions, has a vocabulary that is unique and vibrant. Students of the industry might find these terms useful.

Block—A pulley.

Board foot—A unit of wood that is a foot square and an inch thick. According to the National Association of Home Builders, the construction of a typical 2000-square-foot single-family home requires about 13,800 board feet of lumber.

Boom tender—Loggers who work on the water at the log dump or log pond sorting logs and assembling them into rafts for shipment or processing. The job requires the boom tender to walk on the floating logs, moving dexterously from one to another. Also called a boom poke or a boom cat.

Bucker—This is a logger who bucks trees, that is, cuts them into manageable lengths after they have been felled by the faller. To buck can also mean to pull, as on a cable.

Bull cook—Logging camp assistant, often handles a variety of small duties, including maintaining the bunkhouses, making the beds, and insuring that the camp has adequate firewood.

Butt-rigging—This is the assortment of cables, rings, and knobs that attaches the choker to the mainline. It is maybe named such because it the rigging is attached to the butt of the log (the widest part of the cut tree).

Chaser—The person who removes the chokers from the logs at the landing.

Choker—A short piece of cable wrapped around one or more logs so that they can be hauled to a landing and loaded.

Choker-setter—The person who attaches the chokers to the log.

Cold-deck—A pile of stored logs, often around the base of a spar-tree.

Donkey—A machine, originally steam-powered, that pulls the lines used in yarding and loading lumber at the cut site; it is a type of yarder. Depending on its use, it might also be called a skidder, loader, roader, or flyer.

Donkey puncher—The person who runs the donkey.

Faller—The logger responsible for cutting the tree down (felling the tree).

Groundlead yarding—A method of moving logs by dragging them horizontally across the ground, usually on skidroads, using horizontal rigging pulled, initially, by teams of animals (typically oxen, sometimes horses) and, later, by steam-power donkeys. It was the typical method of yarding logs until about 1910, when high-lead yarding became the standard. (The “lead” in “groundlead” is pronounced like “leed.”)

Guy lines—The unmoving cables used to support and steady the spar-tree.

Hashers—Cookhouse servers, usually women. Also called Queens.

Haulback—Once a log has been dragged out of the woods, the mainline with the buttrigging must be hauled back into the woods and attached to another tree. The haulback is the cable that performs this function.

Highball—Fast moving; also the signal to start reeling in the mainline, often very quickly.

High-lead yarding—A method of yarding in which cut logs were dragged to the landing by a series of cables and blocks suspended in the air from one or more spar-trees and powered by steam, diesel, or gasoline engines. A more efficient and much faster method of moving fallen timber, high-lead yarding became the standard way to move logs early in the twentieth century. It was also called, “overhead,” “aerial,” “airplane,” or “flying machine” logging. (The “lead” in “high-lead” is pronounced like “leed.”)

High rigger—A logger who specializes in climbing and trimming a spar-tree and then attaching the cable guys, rigging blocks and lines to it. Also “head rigger.”

Hooktender—The boss of the rigging crew.

Landing—The place where the logs are dragged for loading.

Line—Steel cable, also known as “wire rope.”

Log dump—A body of water—usually a lake or bay—where logs are dumped to either be sorted and stored for use in a nearby lumber mill or to be assembled into log rafts and towed to distant mills for processing.

Mainline—The heavy cable that is wound up on the drums of the donkey or yarder in order to pull the logs from where they were cut to where they can be loaded.

Peavey—A spiked pole with a hinged tong that is used in moving logs; often used to help break log jams or to sort the timber at a log dump.

Rigging crew—The workers who set up and handle the working lines at a logging site. It is different than the “rig-up crew” which is responsible for rigging the spar trees.

Scale—The number of board-feet of lumber a log contains.

Scaler—A person who calculates the scale of a log in order to determine its value.

Skidroad—A road, usually made out of small logs placed parallel to each other at intervals (like railroad ties), that larger, marketable logs are dragged (“skidded”) along to the landing.

Skidder—Originally a donkey engine rigged to drag logs along the skidroad. Now, a kind of tractor, either with tires or tracked, used to move logs either to a landing or around a yard.

Snoose—Snuff, a strong-flavored chewing tobacco. Its use was common throughout the lumber camps in the Pacific Northwest.

Spar-tree—A tall tree that is trimmed of all branches, topped, then rigged with guy lines and blocks, and used as a derrick to yard logs, moving them from where they were felled to a landing where they can be loaded for shipment to the mill.

Springboard—A tapered wooden plank with a piece of angled iron attached to the wide end. Placed into slots cut into the butt of large trees, springboards allowed fallers to get above the sap-laden bases of the trees to a point where they could more easily cut through the trunk using a combination of axes and long flexible saws called “misery

whips” or “Swedish fiddles.”

Strawline—A small, light cable, often used for hauling gear or riggers to the top of a spar tree. Also called a “jack line.”

Stumpage—The value of standing timber, usually the price a timber contractor will pay a landowner in order log the land. Stumpage often is estimated by the acre or board foot.

Timber cruiser—A person who specializes in surveying a stand of timber and estimating how many board feet of marketable lumber it contains.

Turn—A load of logs.

Whistlepunk—The worker, often young and unskilled, responsible for relaying instructions between the remote worksite and the landing. Before the advent of radio, whistlepunks directed the donkey punchers using a series of whistle blasts actuated by pulling a thin cable.

Widowmakers—Broken limbs shaken loose by fallers. These heavy branches, falling without warning, can kill a logger.

Yard or Yard out—A verb that means to drag a log out of the forest to a landing for shipment to a mill.

Yarder—A machine used to move logs from one point to another. It can be the stationary machine that powers the mainline or a mobile piece of equipment, like a tractor, that hauls logs around.

Sources: Earl Roberge, Timber Country (Caldwell, Idaho: The Caxton Printers, Ltd., 1973), Andrew Mason Prouty, More Deadly than War! Pacific Coast Logging, 1827-1981 (New York: Garland Publishing, Inc., 1985). D. D. Strite, How to Become a Logger: A Complete Treatise in Six Lessons (Portland, Oregon: The Timberman, 1924) and Walter Fraser McCulloch, , Woods Words: A Comprehensive Dictionary of Loggers Terms. (Portland: Oregon Historical Society, 1958).

V. Classroom Exercises

1. Have students use the documents to imagine what working in a logging operation must have been like. Using The Glossary of Logging Terms, D. D. Strite, How to Become a Logger: A Complete Treatise in Six Lessons, and The Whistle Signal Code as sources, have them adopt various roles—for example, high rigger, choker-setter, chaser, or whistlepunk—and write letters home describing what they do and the dangers involved.

2. Ask students to describe the different ways cut timber was transported to lumber mills. Ask them to consider the advantages, disadvantages, and limitations of each.

3. Ask students to describe groundlead and high-lead yarding. Have them describe how geography may have affected the how each was developed and used. Take them outside and ask them to decide which method would work best if they wanted to log their neighborhood (they may need to imagine that it is filled with large trees).

4. Logging has always been a dangerous business and the introduction of steampowered mechanization increased the hazards exponentially. One historian estimates that, by the early part of the 20th century, the typical professional logger had a one in three chance of being killed on the job. Have the students read the excerpt from D. D. Strite’s, How to Become a Logger: A Complete Treatise in Six Lessons. You may want to consider explaining to them that while Strite was writing in a humorous vein, he is describing what it was like for a novice logger working in a high-lead logging operation. Ask them to describe to potential hazards Strite discusses. What seems to be the author’s attitude toward the dangers?

5. Before the use of radios became common, loggers used a variety of whistle signals to pass information and instructions across the distant points of a worksite. In this exercise, designate one student as a “whistlepunk” and provide that student with a whistle. Using the signals adopted by the Pacific Logging Congress in 1930, ask the whistlepunk to pass instructions to the “crew” (the other students). How well were the instructions communicated? Were there any mistakes? Who made them? Could those mistakes had led to accidents? You may want to point out that whistlepunks were often the youngest (sometimes 16) and least experienced worker at a worksite.

6. If the resources are available, acquire a collection of small pulleys and suitable lengths of cord and ask your students, either working in one large group, or several smaller groups, to rig a groundlead operation (use cut broomsticks, small pieces of firewood, or scrap lumber as logs) in the classroom or the schoolyard. Consider assigning roles for example, one student could be designated as the “donkey puncher” and be responsible for pulling the lines in and out. If a sturdy post (like a tetherball pole or a post holding up a walkway) is available, consider setting up a simple model of highlead operation (but be aware you may end up with “flying” pieces of wood). In both exercises the diagrams in the Young Iron Works catalog may be helpful in guiding the projects. Once it is in operation, ask your students to evaluate it. How “complex” is the technology? What are the key components? How could they improve it?

7. Any resource extraction—whether it is timber, oil, gold or something else—is driven by the difference between the price that resource can command in the marketplace and the cost of extracting it from the environment. High prices and low costs typically promote extraction. New technology often both lowers costs and increases the ability to extract resources that were previously unprofitable. Ask students to describe the kinds of technological changes that made logging on the Olympic Peninsula increasingly attractive to profit-minded businesses in the early part of the 20th century. Ask them to think about technology broadly, including things we might term “infrastructure”—like transportation systems. Can they identify other factors that promoted logging in the region?