Cem Millik, a graduate student in the Nelson Lab, is leading an effort to fund the purchase seven commercial-grade 3D printers for use by students across the broader University of Washington Seattle campus. These 3D printers that will be used to establish the Student Innovation Center in the Department of Chemistry, where students will be able to fabricate objects using a wide range of unique materials. The chief advantage of this center is that is will be housed in a space with ventilation hoods that will enable students to use virtually all materials compatible with the two most common types of 3D printers, FDM/FFF and SLA/DLP. For comparison, currently, UW students are essentially limited to printing with a single material, poly(lactic acid) (PLA). This is because the existing 3D printers available to students are housed in facilities lacking the ventilation measures necessary to safely use other materials, which may fume or release particulates during printing. Want to learn more about how students will benefit from the proposed equipment? Read about some of the anticipated project.

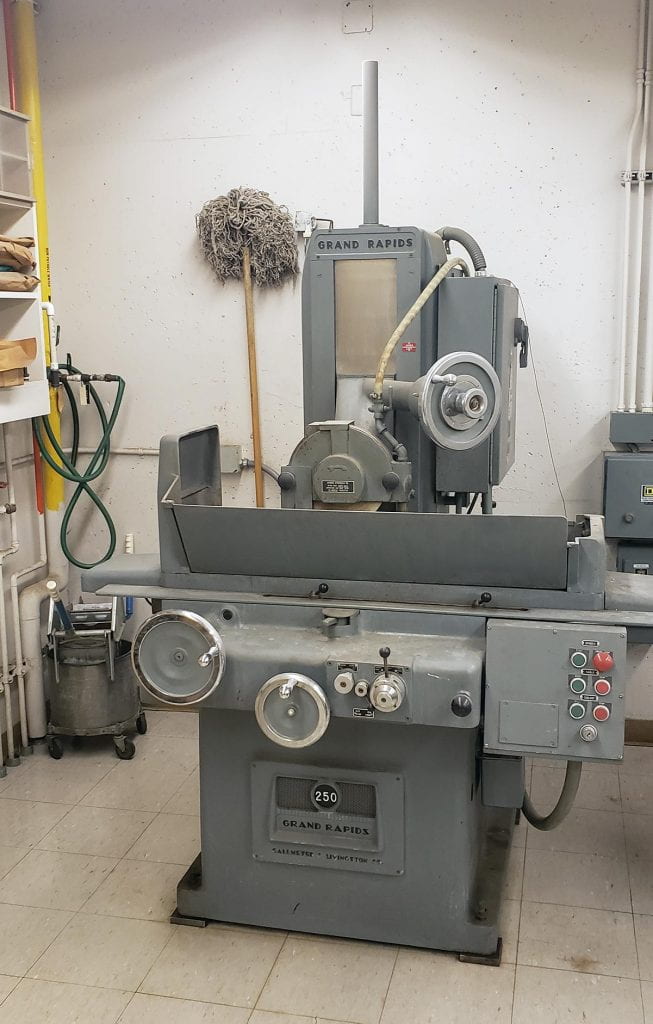

In preparation, Kevin Soderlund has renovated a space adjacent to the Machine Shop with the utilities and ventilation required for the success of this project. We are excited for the possibility of having this new resource on campus!

To learn more about this proposal, visit the Student Technology Fee website. If you would value the acquisition of this equipment and access to these new capabilities and have a UW NetID, we encourage you to consider endorsing this proposal.

You must be logged in to post a comment.